Leser, basınç tahliye valfleri (safety relief valves) ve ilgili basınç kontrol ekipmanları üreten bir Alman şirketidir. Basınç tahliye valfleri, endüstriyel işlemlerde ve ekipmanlarda aşırı basınç durumlarında güvenlik sağlamak amacıyla kullanılır. Leser'in ürün yelpazesi, basınç kontrolü ve güvenliği için çeşitli ürünleri içerir. Leser'in ana ürün kategorileri:

Basınç Tahliye Valfleri (Safety Relief Valves): Leser, farklı uygulamalar için tasarlanmış basınç tahliye valfleri üretir. Bu valfler, basınç yükselmesi durumunda sistemden fazla basınç tahliye etmek ve aşırı basınç durumlarında ekipmanın veya tesisin güvenliğini sağlamak için kullanılır.

Tahliye Vanaları (Rupture Discs): Bu vanalar, belirli bir basınca ulaştığında patlayarak basınç tahliye eden bir tür güvenlik ekipmanıdır. Rupture disc'ler, hızlı ve hassas bir şekilde basınç kontrolü sağlar.

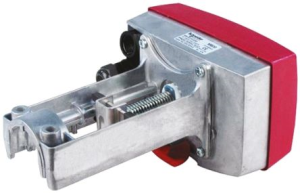

Basınç Şalterleri ve Kontrol Cihazları: Leser, basınç tahliye valfleri ve ekipmanlarının çalışma durumunu izlemek ve kontrol etmek için kullanılan basınç şalterleri ve kontrol cihazları sunar.

Aksesuarlar ve Yedek Parçalar: Basınç tahliye valfleri ve ilgili ekipmanlar için aksesuarlar ve yedek parçalar sağlar.

Leser'in ürünleri, kimya, petrokimya, enerji üretimi, gıda ve içecek, ilaç, su ve atık su yönetimi ve diğer endüstriyel sektörlerde kullanılır. Basınç kontrolü, iş güvenliği ve ekipman koruması için kritik öneme sahiptir.

Bir basınç tahliye vanası, bir sistemdeki basıncı kontrol etmek veya sınırlamak için kullanılan bir emniyet valfı türüdür; Aksi taktirde, basınç birikebilir ve bir süreç zarfında, cihaz,ekipman arızası veya yangın meydana gelebilir.

Basınç tahliye vanası, bir basınçlı tank veya sistemdeki fazla basıncı tahliye etmek için kullanılan bir valftir. Bu vanalar, basınçlı bir sistemi aşırı basınçtan korumak ve patlamayı önlemek için tasarlanmıştır.

Basınç tahliye vanası, basınçlı bir sistemin maksimum izin verilen basınç seviyesine ulaştığında, vananın içindeki bir yay veya piston, valf açılıncaya kadar basınç uygular. Bu açma işlemi, fazla basıncın tahliye edilmesine izin verir ve böylece sistemdeki basınç düşer.

Basınç tahliye vanaları, özellikle buhar kazanlarında ve hidrolik sistemlerde kullanılır. Bu sistemler, yüksek basınç altında çalıştıkları için, patlamaya karşı yüksek risk taşırlar. Basınç tahliye vanaları, bu riski azaltmak için kritik bir güvenlik cihazıdır.